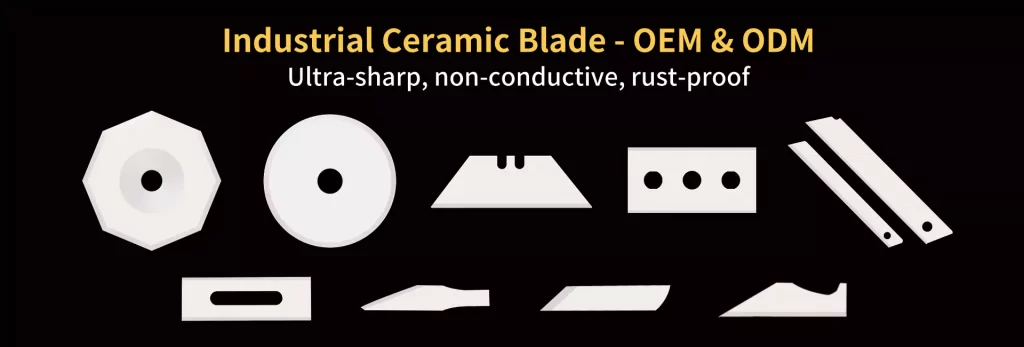

Ceramic mechanical blades find applications in various industries due to their unique properties and benefits. These blades are typically made from advanced ceramics such as zirconia or alumina, known for their hardness, wear resistance, and ability to withstand high temperatures. Here are some common usage scenarios and functions of ceramic mechanical blades:

- Industrial Cutting:

- Ceramic blades are used in industrial cutting applications for materials such as paper, textiles, plastics, and even some metals. Their hardness allows for precise and clean cuts, and their wear resistance ensures a longer lifespan compared to traditional steel blades.

- Food Processing:

- In the food industry, ceramic blades are utilized for cutting fruits, vegetables, and boneless meats. They are non-reactive, corrosion-resistant, and do not impart any metallic taste or odor to the food products, making them suitable for use in sensitive food applications.

- Medical Applications:

- Ceramic blades are used in surgical tools and medical devices due to their biocompatibility and resistance to corrosion. They are employed in procedures where precision and a sterile cutting environment are essential.

- Electronics Manufacturing:

- In electronics manufacturing, ceramic blades are used for cutting and processing delicate components such as silicon wafers, circuit boards, and glass substrates. Their hardness helps achieve precise cuts without damaging sensitive materials.

- Textile and Fiber Processing:

- Ceramic blades find use in the textile industry for cutting fibers, yarns, and fabrics. Their sharpness and wear resistance make them suitable for continuous cutting processes.

- Packaging and Converting:

- Ceramic blades are employed in packaging and converting machinery for cutting materials like films, foils, tapes, and labels. Their durability allows for extended operation without the need for frequent blade changes.

- High-Temperature Environments:

- Ceramic blades can withstand high temperatures without losing their hardness or becoming deformed. This property makes them suitable for applications involving extreme heat or thermal stress.

Functions of Ceramic Mechanical Blades:

- Precision Cutting: Ceramic blades offer high precision due to their sharpness and resistance to chipping, resulting in clean and accurate cuts.

- Wear Resistance: They have exceptional wear resistance compared to traditional metal blades, leading to longer operational lifespans and reduced maintenance requirements.

- Chemical and Corrosion Resistance: Ceramic blades are resistant to corrosion from acids, alkalis, and other chemicals, making them suitable for use in corrosive environments.

- Non-magnetic and Non-conductive: Ceramic blades are non-magnetic and non-conductive, which can be advantageous in certain industries or applications where these properties are required.

- Reduced Friction and Heat Generation: They often exhibit lower friction during cutting, reducing heat generation and minimizing material sticking to the blade edge.

Overall, ceramic mechanical blades offer a range of advantages across diverse industries where their unique properties cater to specific cutting and processing needs.