Introduction:

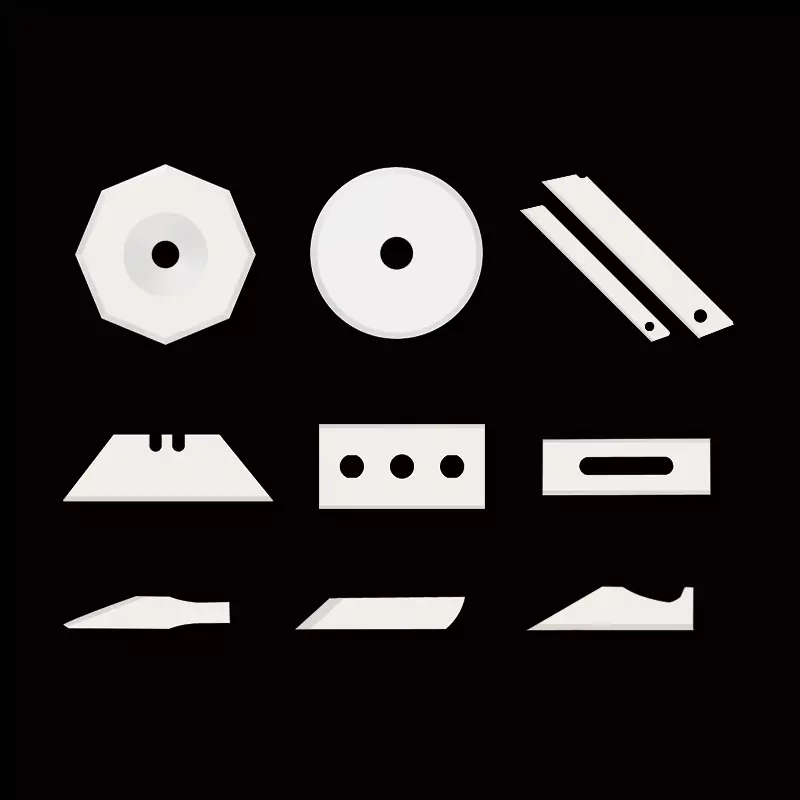

Ceramic zirconia blades have gained popularity in recent years due to their high durability and sharpness. These blades are made from a ceramic material called zirconia, which is known for its toughness, strength, and resistance to wear and tear. In this article, we will explore the properties of ceramic zirconia blades, their advantages and disadvantages, and their uses in various industries.

Properties of Ceramic Zirconia:

Zirconia is a ceramic material that is composed of zirconium dioxide (ZrO2). It is known for its high strength, toughness, and resistance to wear and tear. Ceramic zirconia blades are made by sintering zirconia powder at high temperatures, which creates a dense and homogeneous material with high hardness and sharpness. Zirconia also has a low thermal conductivity, which makes it a good material for cutting applications that generate heat.

Advantages of Ceramic Zirconia Blades:

Ceramic zirconia blades offer several advantages over other types of blades, such as steel or diamond blades. One of the main advantages of ceramic zirconia blades is their high durability. They are extremely resistant to wear and tear, which means they can be used for a long time without needing to be replaced. This makes them a cost-effective option for businesses that require high-quality cutting tools.

Another advantage of ceramic zirconia blades is their sharpness. Zirconia is a very hard material, which means it can be sharpened to a very fine edge. This makes ceramic zirconia blades ideal for cutting applications that require precision and accuracy, such as in the medical or aerospace industries.

Ceramic zirconia blades also offer a high level of chemical resistance. They are resistant to corrosion and chemical damage, which makes them a good option for cutting materials that are difficult to work with, such as composites or ceramics.

Disadvantages of Ceramic Zirconia Blades:

Despite their many advantages, ceramic zirconia blades do have some disadvantages. One of the main disadvantages is their brittleness. Ceramic materials are known for their tendency to crack or break under stress, and zirconia is no exception. This means that ceramic zirconia blades can be more prone to breaking than other types of blades, especially if they are subjected to heavy or sudden loads.

Another disadvantage of ceramic zirconia blades is their cost. Ceramic zirconia blades are generally more expensive than other types of blades, such as steel or diamond blades. This means that they may not be the best option for businesses that are on a tight budget.

Uses of Ceramic Zirconia Blades:

Ceramic zirconia blades are used in a wide range of industries, including the medical, aerospace, and automotive industries. In the medical industry, ceramic zirconia blades are used for surgical procedures, such as cutting bone or tissue. They are also used for dental applications, such as cutting crowns or implants.

In the aerospace industry, ceramic zirconia blades are used for cutting composites and other materials that are difficult to work with. They are also used for precision cutting of components for aircraft engines and other critical parts.

In the automotive industry, ceramic zirconia blades are used for cutting and shaping brake pads, clutch plates, and other components that require precision and durability.

Conclusion:

Ceramic zirconia blades offer many advantages over other types of blades, including high durability, sharpness, and chemical resistance. However, they do have some disadvantages, such as brittleness and cost. Despite these drawbacks, ceramic zirconia blades are widely used in a variety of industries, including the medical, aerospace, and automotive industries, where precision cutting and durability are essential.