It seems like you’re mentioning components related to semiconductor manufacturing. Semiconductor wafer carriers, alumina disks, and ceramic edge rings are essential parts of the semiconductor fabrication process. Here’s some information about each component:

1. Semiconductor Wafer Carrier: A wafer carrier is a specialized container used to hold and transport semiconductor wafers during various stages of the manufacturing process. These carriers are designed to protect the delicate wafers from damage and contamination. They are typically made from materials like plastic, quartz, or ceramic.

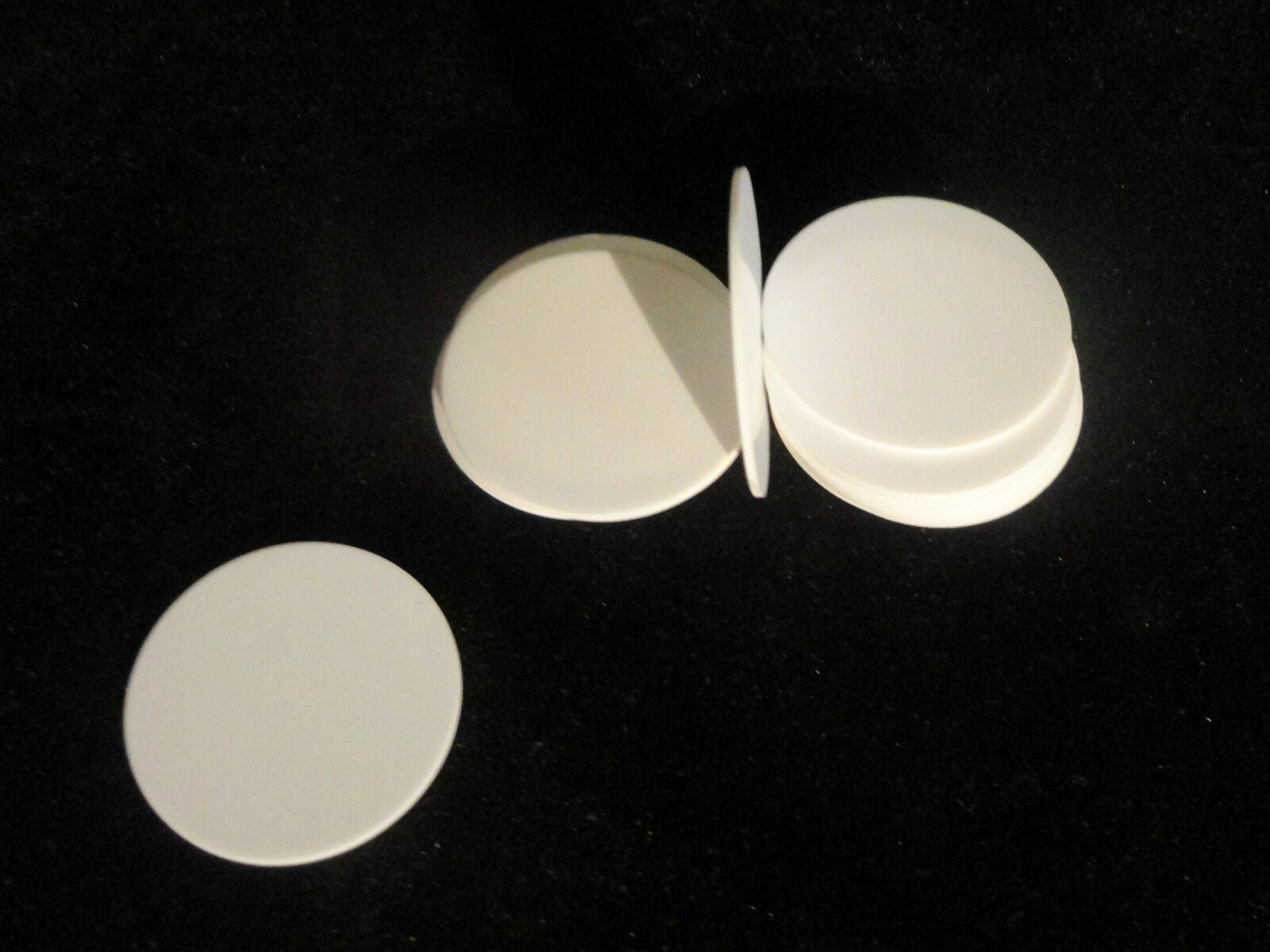

2. Alumina Disk: Alumina, also known as aluminum oxide (Al2O3), is a popular material used in the manufacturing of various semiconductor components, including alumina disks. Alumina disks are thin, flat pieces made from alumina ceramic. They are used in semiconductor processing equipment, such as chemical vapor deposition (CVD) systems and wafer processing tools, due to their excellent thermal and mechanical properties.

3. Ceramic Edge Ring: A ceramic edge ring is a ring-shaped component made from ceramic materials. It is used in semiconductor manufacturing equipment to hold the wafer in place and create a seal during processes like etching, deposition, and chemical mechanical planarization (CMP). Ceramic edge rings are preferred because they are chemically inert, wear-resistant, and can withstand high temperatures and corrosive chemicals commonly used in semiconductor fabrication.

These components play crucial roles in ensuring the precise and contamination-free processing of semiconductor wafers, which is vital for the production of high-quality integrated circuits used in various electronic devices.