Ceramic blades are typically made from advanced ceramics like zirconium dioxide (zirconia) or alumina. These materials possess exceptional hardness and are commonly used in various industrial and consumer applications due to their superior wear resistance, hardness, and chemical inertness.

However, not all blades can be made into ceramic blades. Blades made of metals, such as steel or iron, cannot be transformed into ceramic blades. Ceramic blades are manufactured using powdered ceramic materials that are sintered (heated and compressed) at high temperatures to form a solid, extremely hard material. This process isn’t applicable to metal blades.

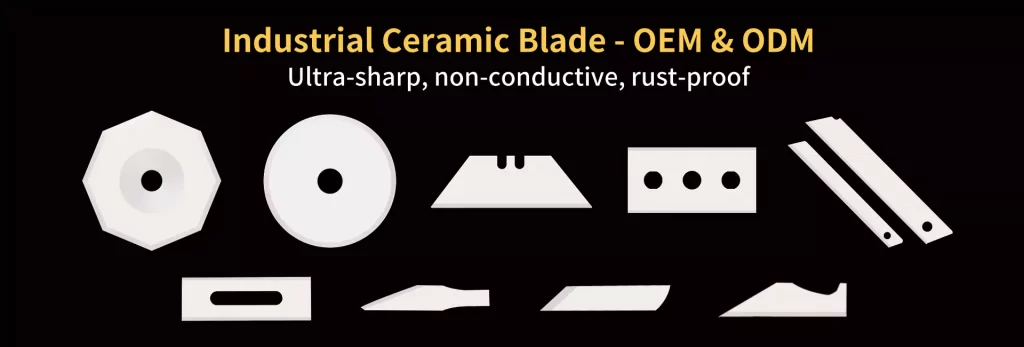

Common types of blades that can be manufactured using ceramic materials include:

- Knife Blades: Ceramic knives are popular due to their sharpness and resistance to corrosion. They’re often used in kitchen cutlery.

- Scissors/Shears: Some scissors and shears have ceramic blades, which can offer durability and longevity compared to traditional metal blades.

- Utility Blades: Ceramic utility blades are used in various industries, offering precise cutting for tasks like paper cutting, box opening, and more.

- Surgical Blades: In certain medical instruments, ceramic blades are used due to their sharpness and resistance to corrosion, though these might be more specialized and expensive.

Ceramic blades are known for their exceptional hardness, maintaining sharpness for a longer period compared to steel blades. However, they are more brittle and can be prone to chipping or breaking if subjected to excessive force or used inappropriately (e.g., on hard surfaces).

Manufacturers create ceramic blades using specific processes designed for these materials, and it’s not feasible to convert existing metal blades into ceramic ones.