CNC (Computer Numerical Control) blades, or CNC cutting tools, play a crucial role in various machining operations across industries. The term “CNC blade” can refer to a variety of cutting tools used in CNC machines. These tools are designed for precision, efficiency, and versatility. Here are some common usage scenarios and functions of CNC blades:

- Milling Operations: CNC blades are used for milling operations to cut and shape solid materials like metal, wood, plastic, etc. They come in various shapes and sizes to perform tasks such as face milling, profile milling, and slotting.

- Turning and Lathe Operations: In turning operations, CNC blades are used to remove material from a rotating workpiece to create cylindrical parts. These tools can perform facing, grooving, threading, and other operations on materials like metal, wood, or plastic.

- Drilling and Boring: CNC blades designed for drilling and boring operations create holes or enlarge existing ones in materials. They maintain precision and accuracy while performing these tasks.

- Grinding Operations: Abrasive CNC blades are used in grinding machines for precision grinding, shaping, or sharpening tools and workpieces. They help in achieving fine surface finishes.

- Engraving and Marking: Specialized CNC blades are used for engraving designs, logos, or markings onto various materials. These blades ensure intricate and accurate results.

- Routing and Cutting: CNC blades are employed in routing machines for cutting, shaping, and hollowing out materials like wood, plastic, or composites. They are used in applications ranging from cabinetry to manufacturing intricate designs.

- Specialized Cutting: Some CNC blades are specifically designed for certain materials or applications, such as high-speed cutting, fine detail work, or roughing operations.

- Composite Material Machining: CNC blades optimized for cutting composite materials like carbon fiber or fiberglass are used in industries like aerospace and automotive for manufacturing parts with high strength and lightweight characteristics.

- High Precision Operations: In industries like electronics or medical devices, CNC blades with extremely fine cutting edges are utilized for precision machining of small and delicate components.

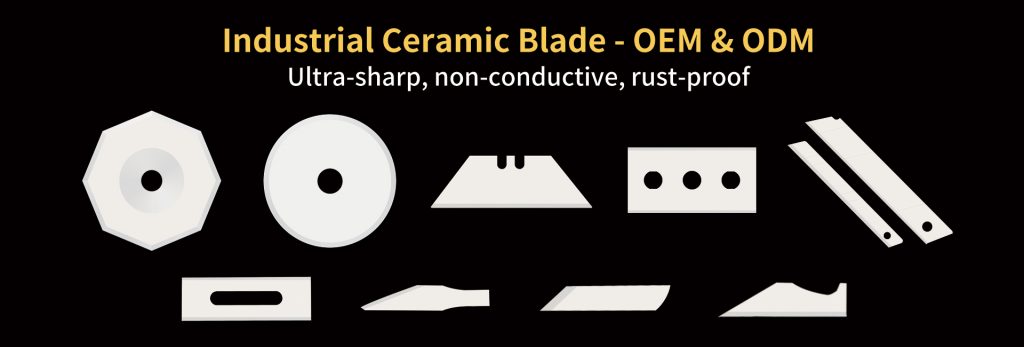

- Automated Production: Ceramic CNC blades are an integral part of automated manufacturing processes, allowing for consistent, accurate, and high-speed production of components across various industries.

These blades are made from different materials such as high-speed steel (HSS), carbide, ceramic, or diamond, depending on the specific requirements of the machining process, the material being worked on, and the desired precision. CNC blades are vital components in modern manufacturing, enabling efficient and precise machining operations across a wide range of industries.