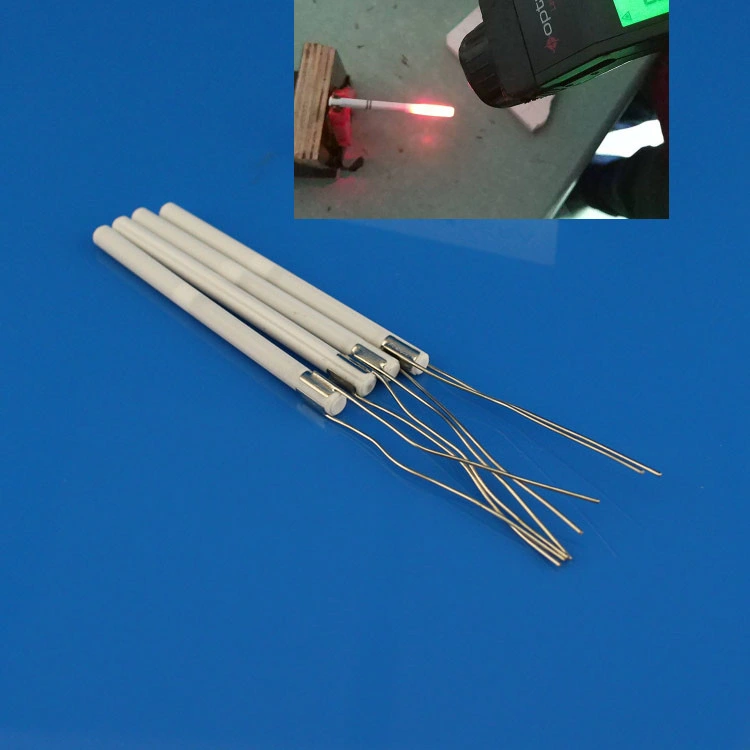

A ceramic heater for a soldering iron is a type of heating element used in soldering equipment. It is made of a ceramic material that has high electrical resistance and excellent heat conductivity. Ceramic heaters are commonly used in soldering irons because they can reach high temperatures quickly and maintain a stable temperature during soldering tasks.

The ceramic heater consists of a ceramic core or tube with a heating coil wrapped around it. When an electric current passes through the heating coil, it generates heat, which is transferred to the ceramic core. The ceramic material efficiently conducts and distributes the heat to the tip of the soldering iron, allowing the user to melt solder and create strong electrical connections.

Ceramic heaters are preferred in soldering irons because they offer several advantages, including:

- Quick Heating: Ceramic heaters can reach the desired operating temperature rapidly, enabling users to start soldering quickly after turning on the soldering iron.

- Temperature Stability: They provide stable and consistent temperature control during soldering tasks, ensuring precision and accuracy in the soldering process.

- Energy Efficiency: Ceramic heaters are energy-efficient, converting a significant portion of electrical energy into heat.

- Durability: Ceramic heaters are durable and can withstand high temperatures, making them suitable for prolonged use in soldering applications.

- Longevity: They have a longer lifespan compared to other types of heating elements, reducing the frequency of replacements.

When choosing a soldering iron, it’s essential to consider the type of heating element it uses, and many professional-grade soldering irons utilize ceramic heaters for their reliable performance and efficiency.