Alumina ceramic and zirconia ceramic are both advanced ceramic materials with high-performance properties. Here are the key differences between them:

1. Chemical Composition:

- Alumina Ceramic: Also known as aluminum oxide, alumina ceramic is made primarily from aluminum oxide (Al2O3).

- Zirconia Ceramic: Zirconia ceramic is made from zirconium dioxide (ZrO2).

2. Crystal Structure:

- Alumina Ceramic: Alumina typically has a hexagonal crystal structure.

- Zirconia Ceramic: Zirconia can exist in three different crystal structures: monoclinic, tetragonal, and cubic. The transformation between these structures can lead to unique properties, especially in the case of partially stabilized zirconia.

3. Mechanical Properties:

- Alumina Ceramic: Alumina ceramics have high hardness, excellent wear resistance, and good mechanical strength. They are often used in applications where hardness and wear resistance are crucial, such as cutting tools and ball bearings.

- Zirconia Ceramic: Zirconia ceramics have exceptional strength, toughness, and resistance to fracture. Zirconia’s toughness is significantly higher than alumina, making it suitable for applications that require high strength and resistance to thermal and mechanical shock, such as dental crowns and hip implants.

4. Temperature Resistance:

- Alumina Ceramic: Alumina ceramics have good thermal stability and can withstand high temperatures.

- Zirconia Ceramic: Zirconia ceramics have even better thermal shock resistance, making them suitable for high-temperature applications where rapid temperature changes occur.

5. Electrical Insulation:

- Alumina Ceramic: Alumina is a good electrical insulator.

- Zirconia Ceramic: Zirconia has relatively poor electrical conductivity, making it useful in applications where electrical insulation is necessary.

6. Applications:

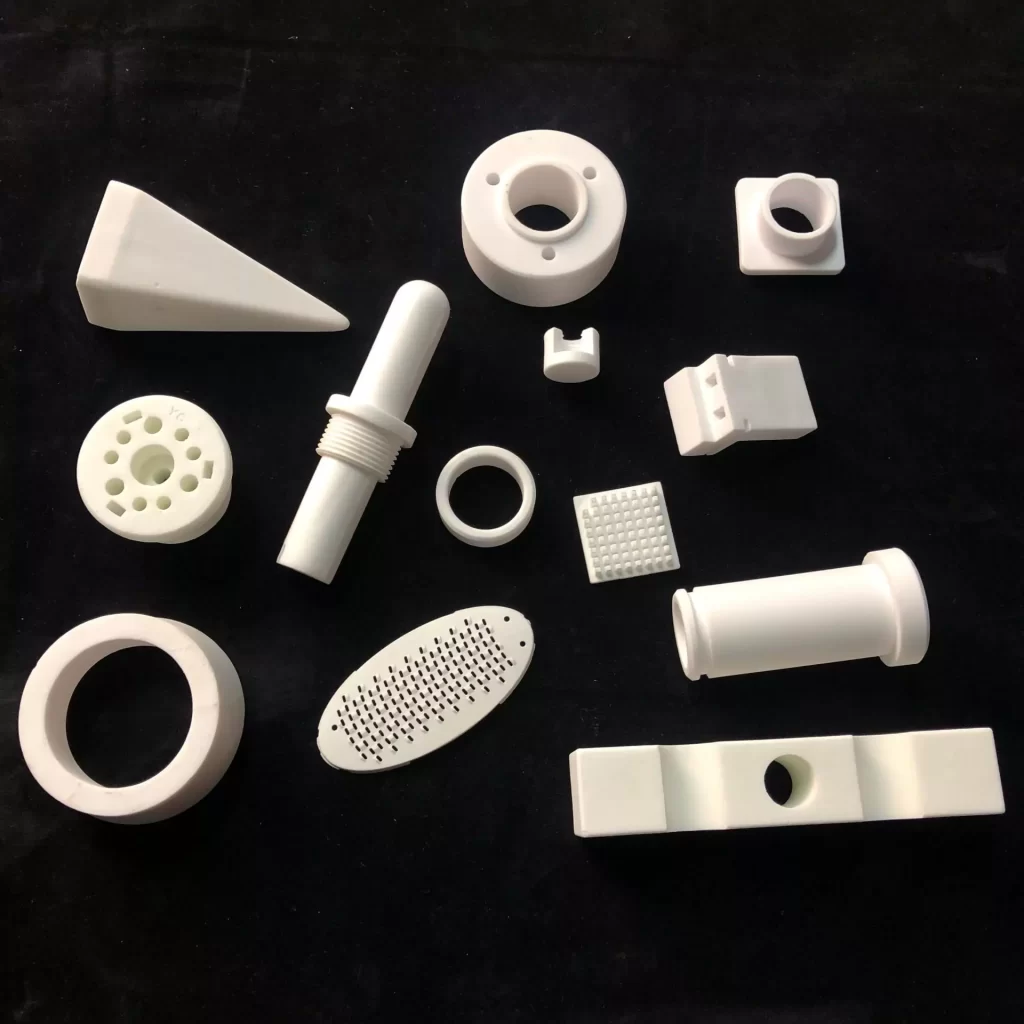

- Alumina Ceramic: Alumina ceramics are commonly used in the manufacturing of cutting tools, electrical insulators, spark plugs, and wear-resistant components.

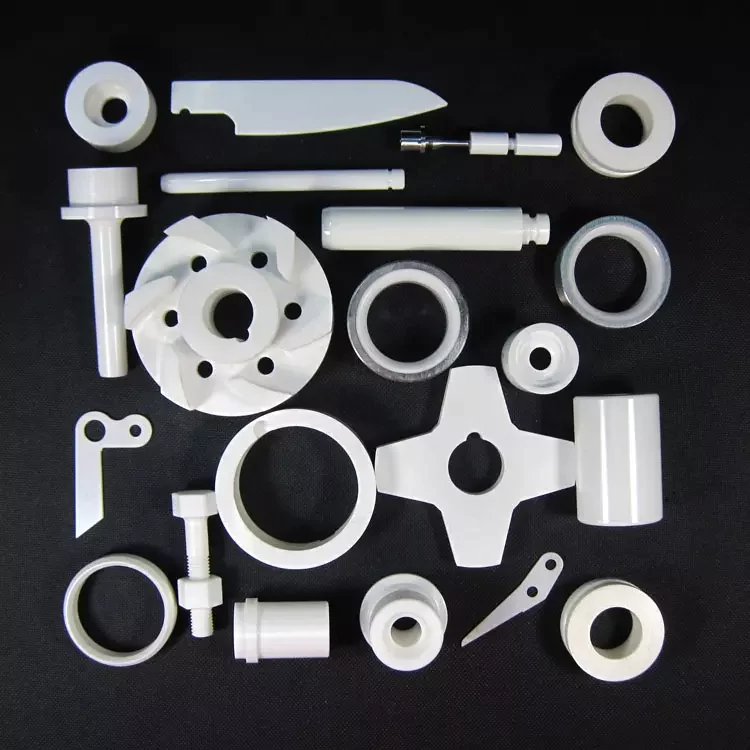

- Zirconia Ceramic: Zirconia ceramics find applications in dental crowns, medical implants, high-performance ball bearings, and various engineering components where high strength and toughness are required.

7. Color:

- Alumina Ceramic: Alumina ceramics are usually white or off-white in color.

- Zirconia Ceramic: Zirconia ceramics can be white, black, or various shades of beige or gray, depending on the specific manufacturing process and impurities.

In summary, while both alumina ceramic and zirconia ceramic are high-performance materials with excellent properties, their differences in crystal structure, mechanical strength, thermal shock resistance, electrical conductivity, and color make them suitable for different applications in various industries.