Introduction

Zirconia ceramics, also known as zirconium dioxide (ZrO2) ceramics, have gained significant attention in various industrial applications due to their exceptional mechanical, thermal, and chemical properties. One of the key factors that determine the suitability of ceramics for specific applications is their ability to withstand high temperatures. This article explores the potential of zirconia ceramics in high-temperature environments, discussing their properties, applications, and challenges faced in extreme heat conditions.

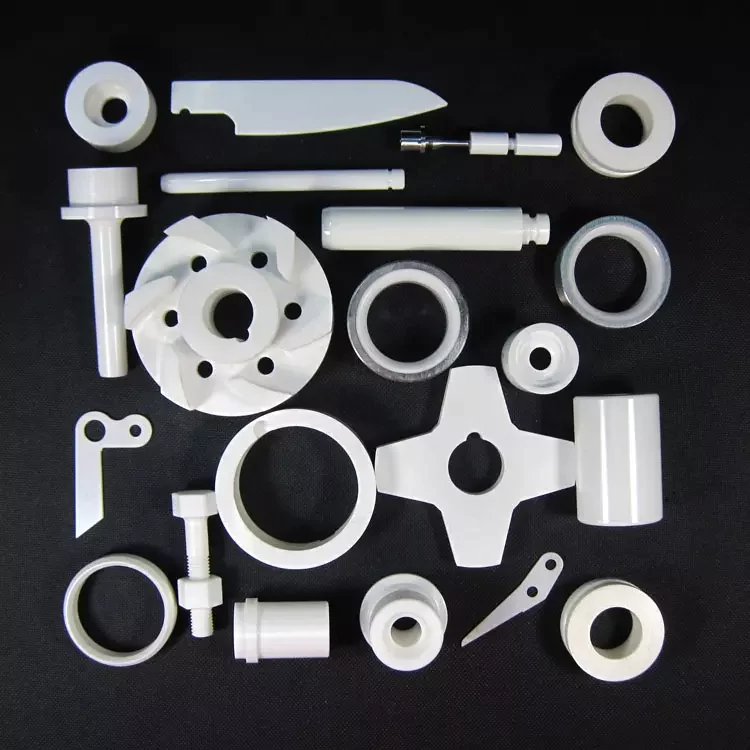

Understanding Zirconia Ceramics

Zirconia ceramics belong to the family of advanced ceramics, characterized by their high strength, hardness, wear resistance, and thermal stability. These ceramics are derived from zirconium, a metal belonging to the transition metal group. Through advanced processing techniques, zirconia ceramics can be engineered to possess varying levels of stability, making them suitable for different applications, including those demanding high-temperature resistance.

Properties of Zirconia Ceramics

1. High Melting Point: Zirconia ceramics exhibit a high melting point, typically above 2700°C, making them suitable for applications in extreme heat conditions.

2. Thermal Stability: Zirconia ceramics possess excellent thermal stability, maintaining their mechanical properties even at elevated temperatures. This property is crucial for applications in industries like aerospace, where components are subjected to extreme heat during operations.

3. Low Thermal Conductivity: Zirconia ceramics have relatively low thermal conductivity, allowing them to act as effective thermal barriers in high-temperature environments. This characteristic is advantageous in applications requiring insulation from intense heat, such as in the manufacturing of crucibles and refractory materials.

4. Chemical Inertness: Zirconia ceramics are chemically inert, resisting corrosion from acids, bases, and other harsh chemicals. This property enhances their durability in aggressive chemical environments, making them suitable for applications in chemical processing industries.

Applications of Zirconia Ceramics at High Temperatures

1. Refractory Materials: Zirconia ceramics are widely used in the production of refractory materials, such as bricks and crucibles, which are essential for high-temperature applications in industries like metal smelting and glassmaking.

2. Aerospace Industry: Zirconia ceramics find applications in aerospace components, including thermal barrier coatings for turbine blades and heat shields. These components operate in extreme temperature conditions, and zirconia ceramics provide the necessary thermal protection and mechanical strength.

3. Ceramic Kiln Furniture: Zirconia ceramics are utilized in the manufacturing of kiln furniture for ceramic and glass industries. Kiln furniture must withstand high temperatures and thermal cycling, making zirconia ceramics an ideal choice due to their excellent thermal stability and resistance to thermal shock.

4. Ball Bearings and Valves: Zirconia ceramics are used to produce high-performance ball bearings and valves for industrial machinery. These components operate at high speeds and temperatures, requiring materials that can withstand the demanding conditions without losing their mechanical properties.

Challenges and Limitations

While zirconia ceramics exhibit remarkable properties at high temperatures, they are not without limitations. One of the significant challenges faced is the risk of phase transformation at specific temperatures. Zirconia can undergo a transformation from a stable tetragonal phase to a monoclinic phase, resulting in a volume expansion and potential degradation of mechanical properties. Researchers and engineers are continually exploring methods to mitigate this phase transformation, such as the addition of stabilizing elements or advanced processing techniques.

Additionally, zirconia ceramics are relatively brittle compared to other engineering materials like metals. This brittleness can pose challenges in applications where impact resistance is essential. However, ongoing research in composite materials and manufacturing techniques aims to enhance the toughness of zirconia ceramics, expanding their utility in high-stress environments.

Conclusion

Zirconia ceramics have proven their worth in various high-temperature applications, showcasing their exceptional thermal stability, mechanical strength, and resistance to chemical corrosion. As technology continues to advance, researchers and engineers are actively working to overcome the challenges associated with zirconia ceramics, ensuring their broader implementation in industries requiring materials capable of withstanding extreme heat conditions.

With ongoing research and development efforts, zirconia ceramics are poised to play a vital role in shaping the future of high-temperature applications across diverse industries. As our understanding of material science deepens and innovative techniques are developed, zirconia ceramics are likely to become even more versatile, opening doors to new possibilities in the realms of aerospace, energy, manufacturing, and beyond. The journey of zirconia ceramics in high-temperature environments is a testament to human ingenuity, driving us toward a future where materials can endure the most challenging conditions, enabling progress and innovation in every field they touch.