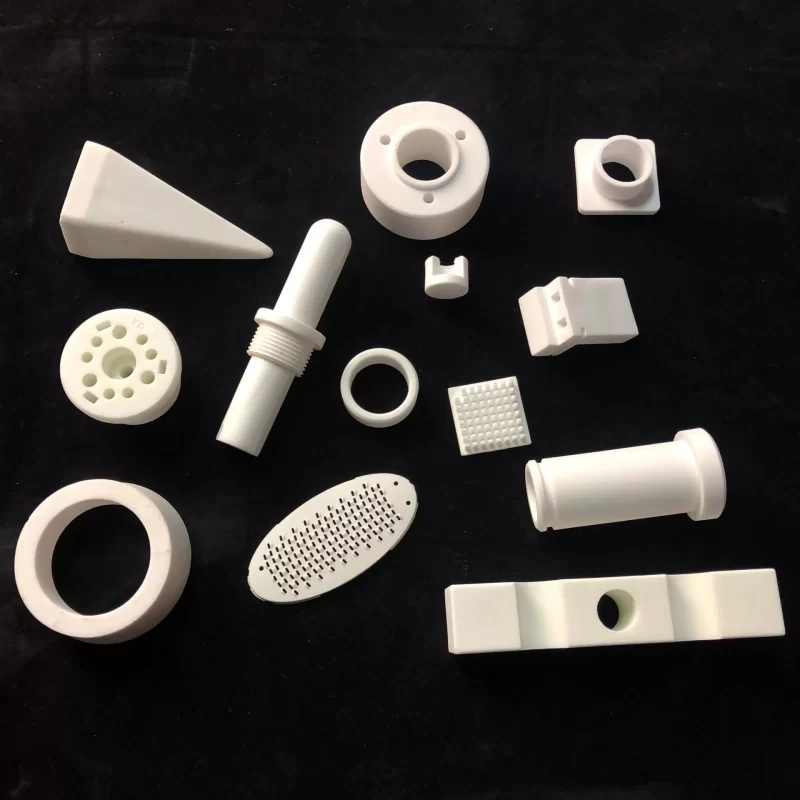

Different types of advanced ceramics:

Alumina

Alumina, or aluminum oxide, represents one of the most extensively employed advanced ceramic materials. This pristine substance, recognized for its purity, hardness (employed in aluminum metal production as an abrasive), and high melting point (applied as a refractory material), has been utilized for numerous years in mechanical and electrical components. Alongside its exceptional attributes of robust mechanical strength, corrosion resistance, superior wear resistance, high compressive strength, and low density, alumina remains among the foremost and widely utilized advanced ceramics. Its applications encompass the production of wear-resistant and heat-resistant liners, lithium-ion batteries, pump seals, electrical insulators (e.g., spark plugs), armor protection, glass, bearings, and more.

Zirconia

Zirconia, also known as zirconium dioxide (ZrO2), is available in both white and black variants, possessing a diverse range of desirable characteristics and exhibiting complete chemical inertness, rendering it suitable for diverse industries. Its remarkable attributes including exceptional wear and abrasion resistance, low thermal conductivity, high thermal shock resistance, impressive mechanical strength, and corrosion resistance position it as one of the most robust and extensively studied ceramic materials. Its applications span various industries such as cutting instruments, aerospace, microengineering, medical devices, electronics, filters, and oxygen gas sensors, owing to its properties similar to alumina.

Silicon Carbide

This technologically advanced ceramic material, relatively rare in nature and primarily found in the mineral moissanite, was initially discovered by Dr. Edward Goodrich Acheson, an American scientist. As the sole chemical compound of carbon and silicon, it yields incredibly durable and robust metals. Originally synthesized through a high-temperature electrochemical reaction of sand and carbon, it serves as an abrasive, refractory resistor, and electric resistor. Silicon carbide’s exceptional hardness of 25Gpa and low density of 3.21gCm-3 make it the preeminent advanced ceramic in contemporary applications, owing to its chemical and thermal properties including high operating frequency and temperature (up to 200c junctions), excellent thermal management, and high energy efficiency.

Silicon Nitride

Silicon nitride, identified as one of the few ceramic materials capable of withstanding severe shock and thermal gradients, finds its application in hydrogen and oxygen rocket science. Renowned for its combination of properties such as good oxidation resistance, mechanical fatigue and creep resistance, low density, and excellent wear resistance, it is employed in various structural applications. Silicon nitride’s hardness, thermal stability, and wear resistance make it ideal for use in engine parts, ball bearings, micro shutters, cutting and shaping tools, as well as exhibiting antibacterial, antifungal, and antiviral properties. Its remarkable mechanical, physical, thermal, structural, and biological attributes position it as a potential candidate for dental and medical implants.

![]()

Cubic Boron Nitride (CBN)

Cubic boron nitride, possessing a diamond-like structure, ranks as the second hardest material after diamond (4500 kg.mm-2 compared to diamond’s 6000 kg.mm-2). Produced by compressing hexagonal boron nitride (h-BN) under high pressure and temperature, CBN functions primarily as an abrasive. Its chemical nature ensures no affinity for low-carbon steel, making it widely used for grinding high-speed steel. With superior thermal and chemical stability, high-temperature stability, high thermal conductivity and electrical resistivity, and chemical inertness, its applications span grinding wheels, tool and armor production, automobile and engine parts, serving as a low-friction component yielding smooth weld surfaces, insulation due to its wide band gap, heat sinks in semiconductor lasers, microwave devices, and LEDs emitting light across a broad spectrum.