Ceramic CNC Blade: Usage scenarios and functions

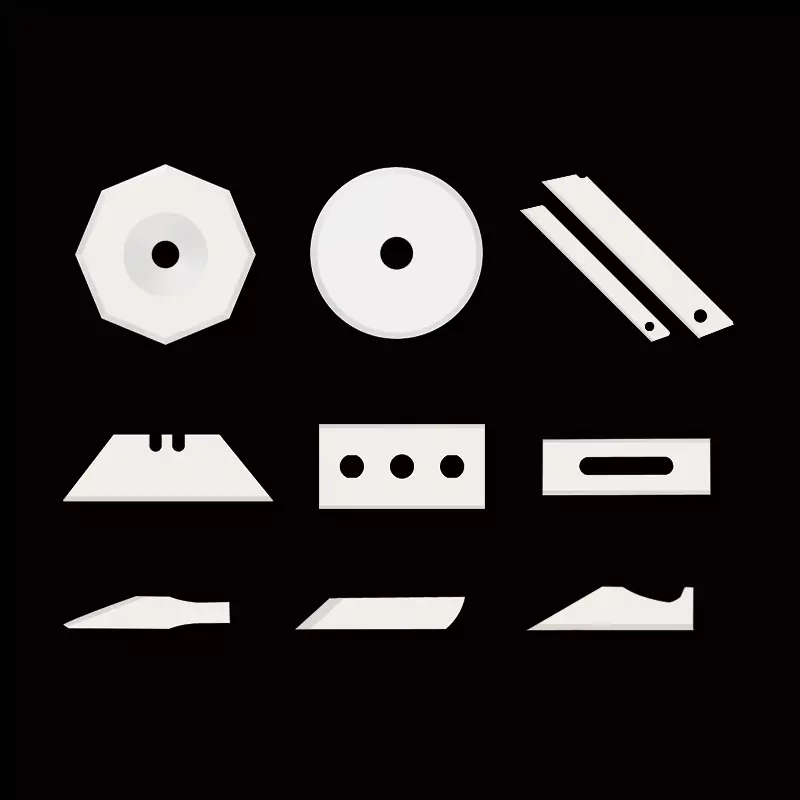

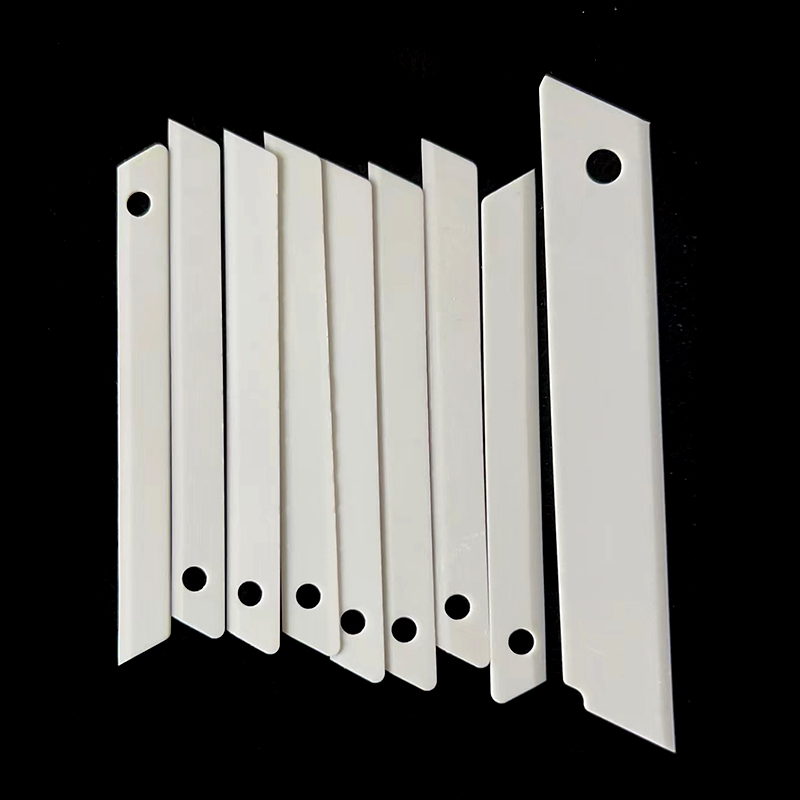

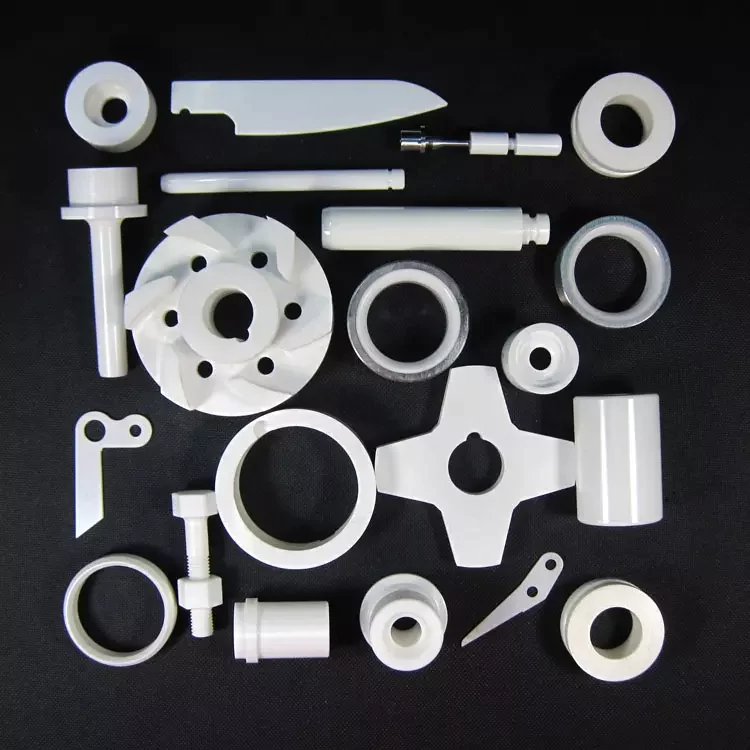

CNC (Computer Numerical Control) blades, or CNC cutting tools, play a crucial role in various machining operations across industries. The term “CNC blade” can refer to a variety of cutting tools used in CNC machines. These tools are designed for precision, efficiency, and versatility. Here are some common usage scenarios and functions of CNC blades: …

Ceramic CNC Blade: Usage scenarios and functions Read More »